Hot Dip Galvanizing in Delhi/NCR

We are not just pioneers in galvanizing chemicals—we also offer state-of-the-art hot-dip galvanizing services to ensure superior corrosion protection for steel structures and components. With a commitment to quality, we deliver durable, long-lasting coatings that meet industry standards.

Hot Dip Galvanizing

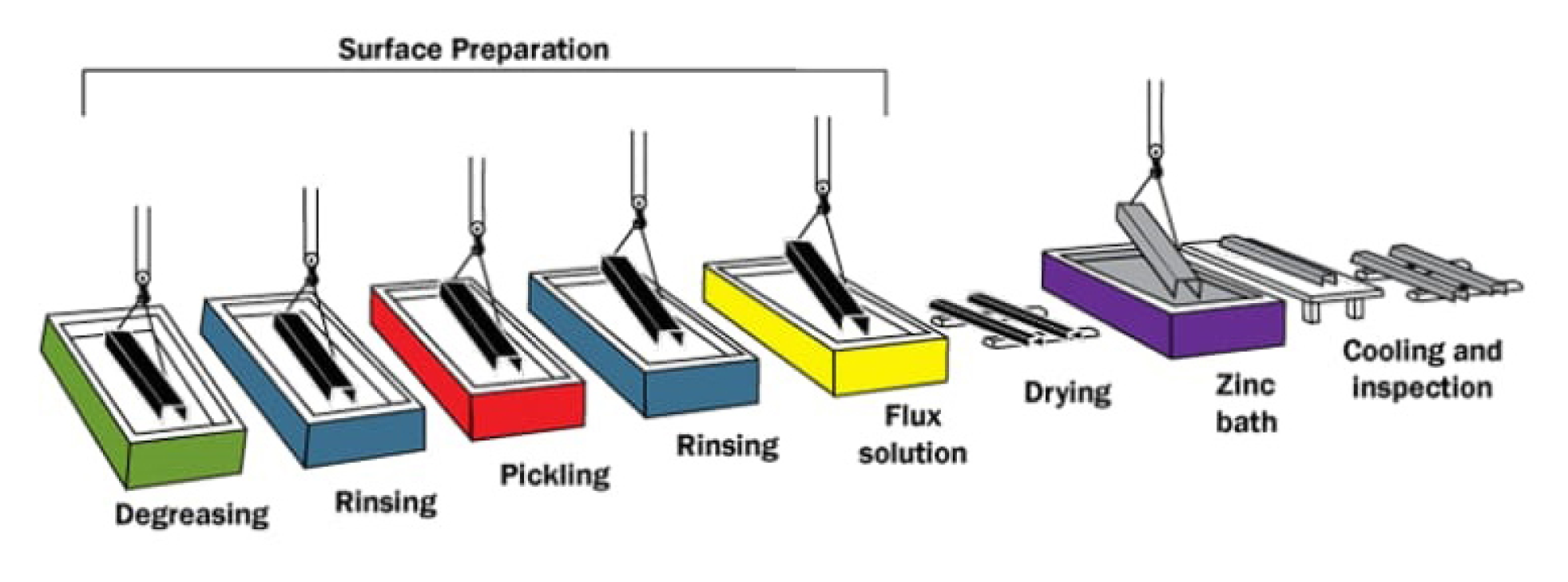

Zinc Bath: This is the core step of the hot dip galvanizing process. In this stage, the cleaned and fluxed steel is dipped into a bath of molten zinc heated to around 450°C (840°F). This creates a tough, corrosion-resistant coating that protects the steel from rust and damage.

Services We Offer

Pre - Treatment Process/Surface Preparation

- Degreasing: Degreasing is the first step in the hot dip galvanizing process. The steel is dipped in an acidic bath, any oil, grease, dirt, or other contaminants on the steel’s surface are removed.

- Pickling: Pickling removes rust, scale, and oxidation from the steel’s surface. The steel is dipped in a diluted acid bath, which cleans off any remaining impurities, preparing it for the zinc coating.

- Fluxing: Fluxing is the final cleaning step before galvanizing. The steel is dipped in a flux solution that prevents oxidation and helps the zinc bond better with the steel. Without this step, the zinc coating can be uneven or weak.

Post - Treatment Process

Passivation: The passivation step in hot dip galvanizing is the final treatment

that protects the freshly galvanized steel from white rust (zinc oxidation)during storage and transport. After the zinc coating cools, the steel is dipped

in a passivation solution

Why Hot Dip Galvanizing?

Most infrastructures have steel in them and it is very important to protect the

steel from corrosion for both longevity and economic point of view. Hot dip

galvanizing has been used worldwide for over 100+ years to protect steel from

rust and corrosion.

Let’s take a look at some of its biggest benefits:

- Superior Corrosion Protection: Hot dip galvanizing creates a tough, metallurgically bonded zinc coating that protects steel from rust and harsh environmental conditions. It offers long-lasting durability even in the most demanding applications.

- Durability & Toughness: The zinc-iron alloy layers formed in hot dip galvanizing are incredibly hard, making the coating resistant to abrasion, impact, and mechanical damage during handling and installation.

- Versatile: Steel is used for many things, but corrosion can damage it over time. Hot dip galvanizing solves this problem by protecting steel while keeping its strength and quality. Plus, this process is widely available around the world, making it easy for anyone to use.

- Fast Turnaround: Compared to other protective coatings, hot dip galvanizing is quick and efficient. Once the steel is prepared, the galvanizing process itself takes only a few hours, helping you meet tight project deadlines.

- Complete Coverage: The immersion process ensures every surface,even hard-to-reach areas like edges, corners, and internal cavities gets evenly coated, offering full protection that other methods can’t match.

- Cost-Effective Longevity: hot dip galvanizing drastically reduces maintenance costs over time. Its extended lifespan means less need for repairs or recoating, making it a smart financial choice.

- Eco-Friendly Solution: The long-lasting protection reduces the need for frequent recoating, minimizing environmental impact over time.

We also have Centrifugal Galvanizing

Centrifugal galvanizing, also called spin galvanizing, is a specialized method

used for coating small, delicate, or threaded steel parts like bolts, nuts, and

fasteners